Why you may belief TechRadar

We spend hours testing each services or products we overview, so that you may be positive you are shopping for the perfect. Find out more about how we test.

I’ve examined out quite a lot of xTool laser cutters earlier than, and I’ve all the time walked away impressed.

Whether or not it is the feature-rich, easy-to-use xTool P2 or the exact xTool S1, I’ve all the time discovered the items to be progressive and correct, rating them among the many best laser engravers and cutters round.

So, I used to be excited to get my fingers on the xTool F2 Extremely. And after some complete testing, let me inform you, this one is in a league of its personal.

The xTool F2 Extremely follows on from the spectacular F1 however boosts pace, energy and design to supply probably the most highly effective but easy-to-use desktop laser engravers available on the market. Whereas the working space may be comparatively small, the truth that it incorporates a 60W MOPA fibre laser enabling you to engrave, emboss and minimize numerous metals is a characteristic that is moderately distinctive. Then there’s the truth that that is coupled with a extra normal 20W diode laser for non-metallic supplies, comparable to wooden, which means that for those who personal a small enterprise, it affords a strong instrument that can allow you to create and customise a variety of merchandise.

While machines like this have been available in the past, they’ve often been ultra-complex and required additional software to handle the speed and power of the fibre laser. However, with integrated software and streamlined workflow, it is pretty much unmatched by any other system I’ve used. I’m pretty confident that even a complete beginner would be able to get up and running with the F2 Ultra.

From the outset, I was impressed not just by the user setup but also by how quick and easy it was to use the xTool software. You just need to select your design, place it over the material in the software, select the material type from the library, then select engrave, cut or emboss before hitting go and watching the design appear within seconds.

The price point of this machine really reflects the quality and speed of what is possible, with the Galvo system enabling speeds of up to 15,000 mm/s and the smart dual-camera setup helping you accurately position items in the machine. It’s impressive what you can do and create in very little time.

Many of the more complex manual setup procedures are removed, with the machine essentially taking over everything, such as focusing automatically. There’s just a small alignment procedure at the beginning of the setup process, but once that’s done, aside from dialling in material and positioning your designs, the machine takes care of everything else.

I’ve used quite a few dual-fibre and diode laser machines in the last year, and while I’m always impressed with what is achievable, there’s usually a bit of tuning and fiddling with calibration and configuring software like LightBurn to accurately mark or engrave. However, here the software aligns everything; you just push the green bar on the control panel, and the machine takes care of the rest.

With the F1, I was impressed by the speed, utility and flexibility of the machine, but the F2 Ultra is in another league, obviously reflected in the price point. Compared with any other system on the market, the F2 Ultra, especially when coupled with the conveyor belt, offers a huge amount of options and possibilities. For any small business dealing with laser engraving and embossing, there’s now only one machine, the F2 Ultra.

xTool F2 Ultra: Price & availability

The xTool F2 Ultra is available on xTool’s official site – it’s priced at $4999 in the US and £6029 in the UK.

I am additionally seeing the unit retailing for $5499 on Amazon.com. Nonetheless, it does not look like obtainable on Amazon.co.uk on the time of overview.

xTool F2 Ultra: Design

Specs

Laser Technology: Dual-laser: 60W MOPA fibre + 20W blue diode

Work Area: 220 × 220 mm (expandable to 220 × 500 mm with conveyor)

Spot Size: 0.03 × 0.03 mm (fibre); 0.08 × 0.06 mm (diode)

Engraving Speed: Up to 15,000 mm/s

Positioning Accuracy: Up to 0.0001 mm

Camera System: Dual 48 MP with AI recognition

Dimensions: 730 × 320 × 265 mm

Weight: 20 kg

Supported Materials: Metals, wood, acrylic, leather, glass, ceramics, plastic

Safety: Fully enclosed with auto-shutdown and fire detection

Software: xTool Creative Space + LightBurn compatible

One of the standout features of the xTool products is just how well-designed they are. This is from a company that, a few years ago, was producing simple open-frame laser cutting machines with a distinct DIY feel. Those machines are far removed from the F2, which is highly refined and of exceptionally high quality, aimed at small to medium-sized businesses rather than the casual consumer or prosumer.

While the machine itself is relatively compact with a footprint that will sit perfectly on a desktop, it has a high-quality build that reflects not only its price point but also its suitability for years of use.

The machine is relatively simple, with a slide-up enclosure that encloses the working area. If you need to have it open for larger materials, that’s possible. There’s also the ability to add an air filter to extract fumes, and as you’d expect with a professional-level machine, there’s a kill switch and a decent touchscreen display to monitor the process and access many settings.

As with many other laser engravers and CNC machines, most interaction is done through complementary software. xTool provides its own ecosystem, which is one of the best on the market, streamlined and easy to use. Unlike some other fibre lasers, there’s no need to purchase expensive extra software or plug-ins. Once you’ve paid (admittedly a lot) for the F2 Ultra, it should work out of the box and be set up within about 10 to 15 minutes.

The design is also clever in that you can use it as a fully enclosed system with smart safety features like emergency stop, flame detection, and automatic shutdown when open, or bypass some of those for conveyor belt use with larger objects.

In terms of size and weight, it comes in at roughly 20 kg and measures 730 × 320 × 265 mm. This smallish footprint will sit comfortably on your desktop, though you do need to allow for the machine’s height and a small side control panel.

If you’re using the conveyor belt, you’ll need even more space. It’s an optional extra, but if you’re planning to use it, it’s well worth having a full workbench left free to easily operate the machine.

On initial setup, I used the USB connection to sync with my laptop. After initial calibration, I switched to the Wi-Fi connection, which I found strong and reliable, even on my underpowered workshop network.

The overall build is premium and extremely sturdy. The two internal cameras and full autofocus add to the ease of use and high-end feel. However, compared with something like the ComMarker B6, it is a far bigger and heavier machine.

xTool F2 Ultra: Features

The F2 Ultra is an interesting machine as it combines two laser types in one enclosed engraver. The first is a powerful 60W MOPA fibre laser used for engraving, embossing and cutting thinner metals, the second laser is a 20W diode laser used for cutting and engraving organic materials such as leather and wood.

Not long ago, it was unusual to find both lasers in one machine, but as we saw with the ACMER P3, combining the two is becoming more common. The big difference between the Atomstack P3 and the xTool F2 Ultra, aside from the price, is the build area. The ACMER P3 is designed for far larger objects, while the F2 Ultra features a far more powerful fibre laser and is designed for more intricate work. In terms of product design and finish, the F2 Ultra is in another league.

One of the biggest advantages of having a dual-laser system is that it enables automatic switching between laser types depending on the material. In the past, other machines with dual lasers required you to manually swap out the tool heads, fibre or diode. We’ve seen this before with older xTool and Creality machines.

The fibre laser not only cuts through thin metals but also enables colourful anodisation of aluminium and steel. The diode laser can cut through relatively thick organic materials, ideal for a 3mm base ply, and in some cases up to 20mm in thickness.

In terms of laser power, the MOPA fibre laser for metals comes in at 60W, which is extremely powerful for this type of machine. The 20W blue diode laser is mid-range but perfectly suited to the small platform and build area the F2 Ultra offers.

When it comes to engraving speed, the fibre laser uses Galvo scanning technology, enabling speeds up to 15,000 mm/s. This sounds fast, and when you see it in action, it is. You can engrave a MacBook Pro in a matter of seconds, although, while the temptation was there to do so in this review, I held off, at least for the moment.

The more I used the machine, the more impressed I became with its features. The dual 48MP cameras enable AI-powered alignment, making a real difference to positioning. The cameras feed into the xTool software, allowing for precise placement on the material. With a positioning accuracy of up to 0.0001 mm, even the finest materials are handled with extreme precision.

While the working area of the F2 Ultra is smaller than many large-scale engravers, it’s designed for small businesses looking to engrave and cut smaller items. The base size is 220 × 220 mm, which suits a wide variety of objects. If more space is needed, a conveyor accessory expands this to 220 × 500 mm.

One of the areas that excited me most was the precision; the fibre laser offers a spot size of 0.03 × 0.03 mm and the diode laser 0.08 × 0.06 mm, allowing for extremely fine detail.

Thanks to the dual-laser setup, there’s decent material compatibility, most notably stainless steel, aluminium, titanium, gold, and even silver. With very thin materials, it’s possible to cut as well as engrave metal, which is rare even among fibre laser engravers, but that additional power boosts that potential.

The machine also handles all the usual materials, acrylic, leather, rubber, ceramics, and glass (though some surfaces may require preparation). It’s designed for precision, not bulk processing, and while cheaper machines exist for large-scale cutting, the F2 Ultra excels in high-quality, fine-detail work.

Supporting that precision are smart features like smart focus, autofocus, and automatic Z-axis adjustment. Unlike other engravers, where you manually enter material thickness or use gauges, this machine does it all for you.

The fully enclosed enclosure offers Class 1 safety so that you can be sure to be protected from those high-power lasers, which, if you’re using this in a small workshop or shop, is well worth considering. Built-in sensors include flame detection, which triggered several times during testing when pushing the machine’s limits of power, and an emergency stop is also available.

xTool also supplied a smoke filtration unit, which connects to the machine and keeps fumes to a minimum. This is an optional extra, but if you’re spending on the F2 Ultra, it’s well worth the investment.

Although the F2 Ultra is well above many machines I’ve tested in terms of quality, it still supports popular laser engraver accessories, including the rotary tool, conveyor feeder, and air-assist smoke purifier, all of which enhance cut quality and streamline workflow.

As for software, I really like xTool Creative Space. It’s fully featured, with helpful tools and instructions, and is very easy to use for laying out designs. If you’re a more advanced user, the machine is fully compatible with LightBurn, although you’ll need the Galvo plug-in. Once installed, all the cameras and configurations work through that as well.

xTool F2 Ultra: Performance

Starting out with the xTool F2 Ultra, this is one of the easiest machines I’ve come across to set up and use of its type. While the machine is relatively large, its actual footprint is quite compact, meaning it sits comfortably on your work surface without taking up too much space. It’s more vertical than wide or deep.

Once positioned, with the dongle and control panel plugged in, you can switch on the machine, and it runs through its initial checks, ready for calibration. I connected it to my MacBook Air via USB and used the Creative Space software to complete the alignment and calibration process. This involved placing a piece of material inside, clicking ‘next’, and allowing the software to mark two points, which were used to align everything automatically. Once complete, the machine was ready to go.

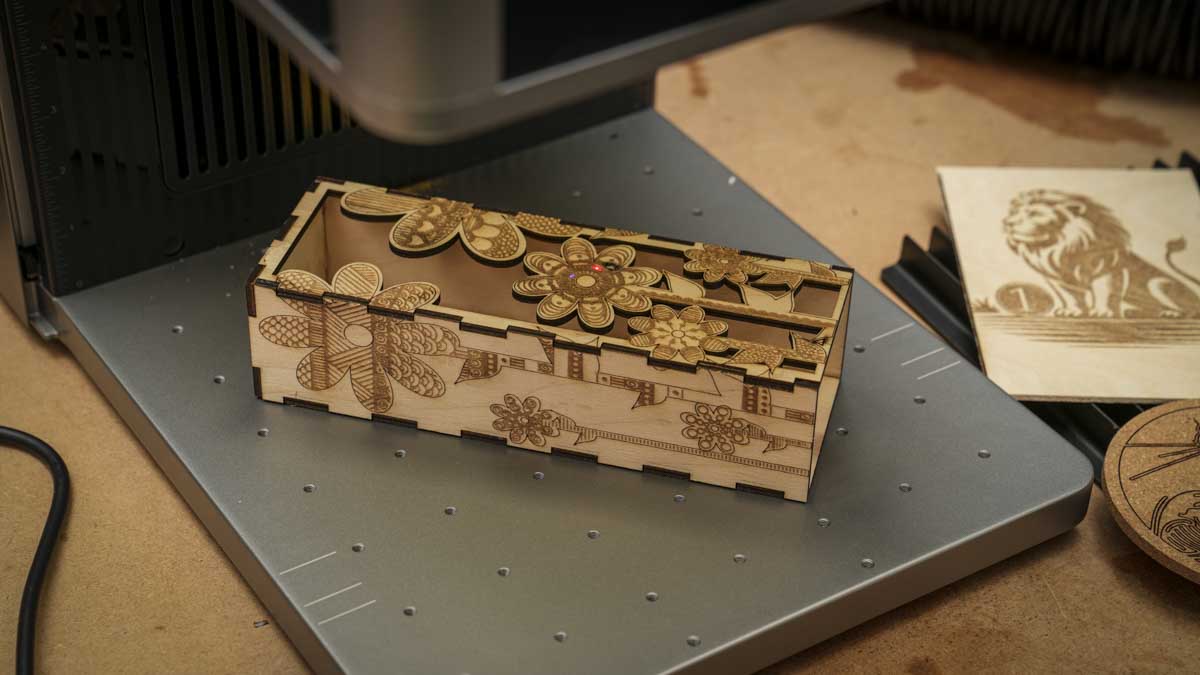

In the box with the review sample were a few test materials. Over a three-hour period, I cut, engraved, and embossed various items, from metals to wood and leather, and was impressed by how quick and easy the machine was to use. I liked that the fully enclosed nature meant I could just pull down the lid, hit start in the software, then press the green bar on the control panel and watch the engraving, cut, or emboss process begin.

In almost all cases, the output quality was excellent. Only the first few materials required some adjustment as I got a feel for the machine’s power. For example, my first attempt at engraving a 3mm base ply used too much power and burned the material to ash. On the second run, the result was far better. The standard 20W diode laser was very capable, and with the air assist and smoke filter extracting fumes, the quality and precision of the cut were impressive.

One thing I really liked, whether working with metal, wood, or leather, was the camera-assisted positioning. Through xTool Creative Space, you can capture a live image of the material on the work area and place your design directly on top. This allows for near-100% accurate placement.

If you’re unsure about positioning, you can also click the ‘frame’ button, which projects your design outline onto the material inside the machine. This projection is sharp and precise, allowing for fine adjustments before committing to a cut or engraving.

As with any laser engraver, I ran a series of test passes on different materials, especially metals and woods, to get a feel for the required power and speed settings for both diode and fibre lasers. Although the 20W diode laser is mid-range by today’s standards, its power and accuracy deliver clean, high-quality cuts through 3mm base ply.

Switching to the fibre laser highlighted just how capable this machine is. The 60W power output provided more engraving depth than I’ve seen in other fibre lasers I’ve tested, and the speed and accuracy are unmatched so far.

For the first few engravings, I used sample files included with the software, most of which completed in a few seconds. Even though I know these machines are fast, the speed of the xTool F2 Ultra still surprised me.

One of my early projects was engraving a set of dog tags for my dog and a few friends. Usually, this might take a few attempts to get right, but here, the accuracy and speed were such that each tag was engraved in under five seconds.

What’s more, by laying out a batch of tags on the surface and applying different text to each through the software, I was able to engrave up to 20 tags in one go and faster than anything I’ve used before.

The more I used the fibre laser, the more intuitive the software became. Unlike other fibre lasers that take time to learn and have complex configuration steps, with the F2 Ultra, I felt confident within an hour, engraving coins included in the material pack with intricate designs.

The small work area is ideal for this kind of precision engraving. But of course, this is a dual-laser machine, and I wanted to test the diode laser on more materials. I engraved the cover of a book, lowering the laser power to about 5% and increasing the speed. After a few test dots to fine-tune power levels, I ran the full design, which was completed in under a minute with excellent quality.

As I continued engraving tools, creating more coasters and keyrings, the one thing that stood out was the precision of the engravings. When using my own materials, I learned that careful attention to power and speed settings was essential. My first batch of coasters burned quickly, but a test pass and adjustment solved that.

The quality of the lines, especially with air assist and the filter removing fumes, was excellent. That said, the limited work area is noticeable. This machine is built for precision tasks, not large-scale projects. For that, something like the xTool P2 would be more appropriate.

All this use was good and standard, but the point of the F2 Ultra is that it’s far more, especially with the ability to emboss metal. How you do this isn’t exactly straightforward initially, as there’s a little delving into the menu; the same is the case when using the Rotary attachment. Essentially, in the XCS software, you click the Select Processing Mode, then scroll down past the “Roller – Use Rotory attachment”, “Use Converyor Large” to the “Emboss” option. Once selected, you can then start to lay out your chosen design.

The next step is to select the material, in this case, a brass coin blank supplied by xTool. This is selected from the material menu; here, you need to select “More Materials”, type in Brass and 1.57″ (40mm) Blank Commemorative Coins Brass” will appear. From here, you can select the material, select the F2 Ultra, then click “Add to XCS”. Then click back onto the material and select the “1.57” (40mm) Blank Commemorative Coins Brass.

Now the coin can be placed into the F2 Ultra, and by clicking “Refresh Background” then “Auto Measure”, the coin will appear on the screen, ready for you to position the design.

The design is the next stage of processing, as a straight image won’t get you the emboss effect, and a depth map needs to be created.

To do this, you click the “Ai” icon, select “Image Processing”, and select “Embossment”. You’re then given the option to upload your image, select the Emboss type, and then click “Generate” Once the processing is finished, you can drag and drop the coin design onto the workspace and over the preview of the coin. Once you’re happy, you can click process, and the embossing will start. For most projects, this process is considerably slower than general engraving and can take well over an hour; however, the end results are incredible, especially once polished and finished off.

It’s worth noting that the depth map creation isn’t an exact science, and there’s no way to adjust the map, but after a while and with the 3D preview, you start to get an idea of what works and what doesn’t.

By the end of the test, I was genuinely impressed by the fibre laser, which is clearly the core of the F2 Ultra. The inclusion of a powerful diode laser fine-tuned for detailed work adds even more versatility, ideal for small businesses.

It’s clear this machine is designed for small to medium-sized businesses that rely on laser engraving, whether to create and customise products or for crafts requiring precision, such as jewellery work. It offers a level of detail and reliability that many other fibre and diode systems cannot match.

xTool F2 Ultra: Final verdict

The xTool F2 Ultra is one of the best fibre laser engravers on the market, with a premium build and a product-designed enclosure that makes it an ideal option for many small to medium-sized businesses. It’s perfect for small-scale production, customisation, and any business that needs to laser engrave a wide range of surfaces. What it is not is a large-scale laser engraver for oversized projects. This is focused on absolute precision.

The inclusion of two lasers and the dual cameras for AI alignment onto smaller objects helps ensure ultimate precision. If you need to do batch engraving, it speeds up the entire process, essentially handling much of the setup and configuration for you.

After using it for a month, this is by far the best fibre laser engraver I’ve tested. The major downside is the cost. The base machine is expensive, and once you add in the conveyor, rotary tool, and smoke filtration units, though combo packs are available from xTool, it still adds up to several thousand pounds, which is a considerable investment for a small business.

However, this is a professional machine. It’s not just a starting point; it’s a system you can build your business around. Its precision and quality are high-end, and if you’re looking for a solid, reliable machine to support or expand your business, the F2 Ultra is an obvious choice.

What I also appreciate is how well xTool Creative Space is designed. It’s robust, intuitive, and simple to use. While you can use third-party options like LightBurn, which offers more advanced control, you will need the Galvo plug-in and some setup time to get everything calibrated properly.

For experienced users, this opens up even more potential; however, if you’re a small business looking for a fast and versatile laser engraver, the F2 Ultra stands out as the best option on the market. Paired with one of xTool’s straight diode machines, it gives you a powerful ecosystem capable of handling a huge variety of projects with ease and speed, making it a sound investment.

|

Value: |

Premium machine for pro users with deep pockets |

4 |

|

Design: |

Durable, enclosed, and workbench-friendly layout |

4.5 |

|

Features |

Dual-laser + AI + Galvo = professional flexibility |

5 |

|

Performance |

Flawless output across materials and batch work |

5 |

|

Total |

Among the best all-in-one engravers available today |

5 |

Buy it if…

Don’t buy it if…

For more crafting tech, I’ve tested and reviewed all the best 3D printers.