A technique to do this is known as distant epitaxy, the place an intermediate layer made out of graphene or different materials is launched between the substrate and the rising crystals. As soon as the epitaxy course of is finished, the substrate and every part on it are soaked in a chemical resolution that dissolves this intermediate layer, leaving the crystalline movie intact. This works however is dear, troublesome to scale, and takes a variety of time. To make the method cheaper and quicker, the MIT staff needed to develop the crystals straight on the substrate, with none intermediate layers. What they had been attempting to realize was a non-stick frying pan impact however at an atomically small scale.

Weakening the bonds

The fabric that prevented the crystalline movies from sticking to substrates wasn’t Teflon however lead. When the staff was experimenting with rising totally different movies of their earlier research, they seen that there was a cloth that simply got here off the substrate, but retained an atomically easy floor: PMN-PT, or lead magnesium niobate-lead titanate.

The lead atoms within the PMN-PT weakened the covalent bonds between the movie and the substrate, stopping the electrons from leaping by way of the interface between the 2 supplies. “We simply needed to exert a little bit of stress to induce a crack on the interface between the movie and the substrate and we might understand the liftoff,” Zhang instructed Ars. “Quite simple—we might take away these movies inside a second.”

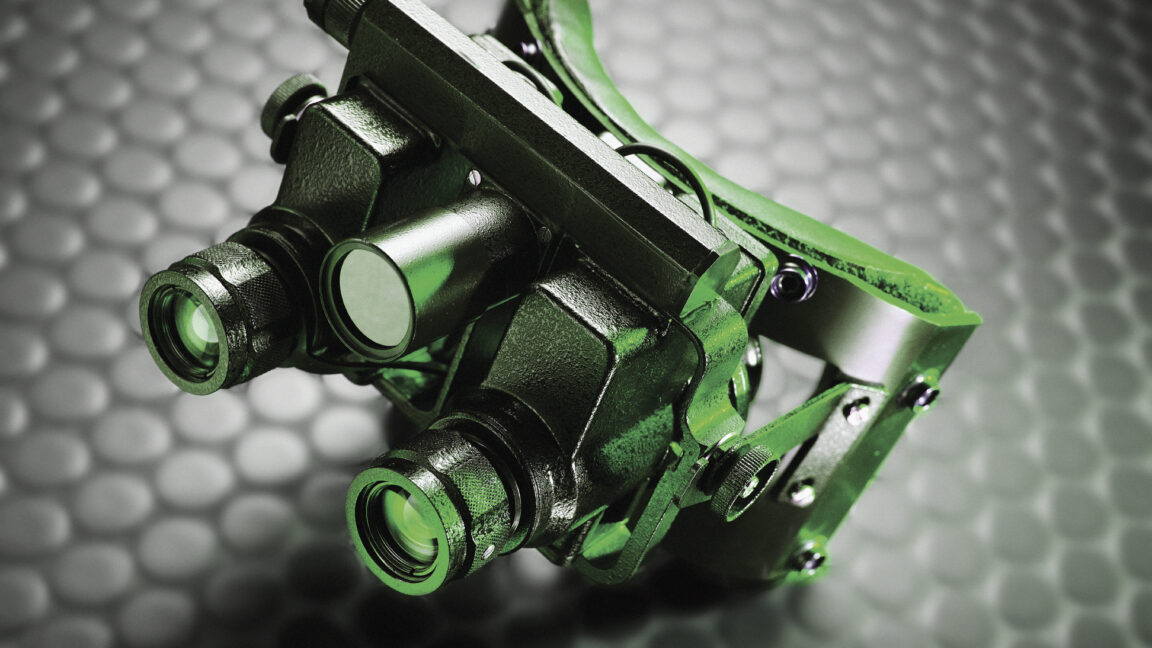

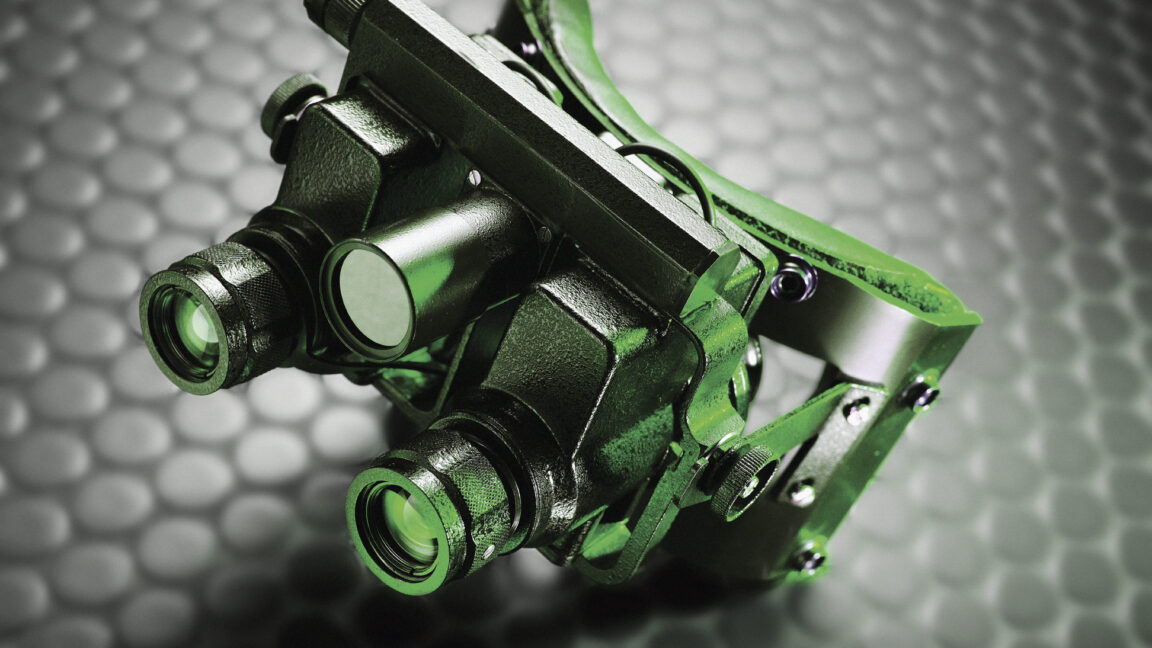

However PMN-PT, in addition to its inherent non-stickiness, had extra tips up its sleeves; it had distinctive pyroelectric properties. As soon as the staff realized they might manufacture and peel away PMN-PT movies at will, they tried one thing a bit extra complicated: a cooling-free, far-infrared radiation detector. “We had been attempting to realize efficiency comparable with cooled detectors,” Zhang says.

The detector they constructed was comprised of 100 items of 10-nanometer-thin PMN-PT movies, every about 60 sq. microns, that the staff transferred onto a silicon chip. This produced a 100-pixel infrared sensor. Exams with ever smaller adjustments in temperature indicated that it outperformed state-of-the artwork night time imaginative and prescient programs and was delicate to radiation throughout your entire infrared spectrum. (Mercury cadmium telluride detectors reply to a a lot narrower band of wavelengths.)